In today’s throwaway culture, consumers often find themselves replacing entire appliances or tools because of a small broken plastic part. Whether it’s a cracked hinge on a dishwasher, a snapped bracket in a vacuum cleaner, or a worn-out gear in a power tool, the result is often the same: the entire device becomes unusable. Worse still, many of these parts are no longer in production or are prohibitively expensive to replace. That’s where my specialized service comes in—providing a custom design and manufacturing solution for small plastic components using CAD/CAM technology and high-precision 3D printing.

What the Service Offers

My service focuses on the accurate recreation, redesign, and manufacture of small broken plastic parts that are otherwise difficult or impossible to find. Using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) tools, I digitally reconstruct broken or missing components. Once the design is finalized and tested virtually, I manufacture the part using 3D printing technology with high-performance thermoplastics such as PLA, PETG, or ABS.

This process allows for the rapid production of parts that are tailor-made to fit your specific application, often improving upon the original design for better durability and performance.

The Process in Detail

1. Initial Assessment

The process begins with a consultation and evaluation. You provide photos, sketches, or the broken part itself. In some cases, multiple images from different angles and measurements with calipers or rulers are sufficient. For more complex pieces, I may request the damaged part so I can reverse-engineer it directly.

2. 3D Modeling Using CAD

Using advanced CAD software such as Fusion 360 or SolidWorks, I create a detailed digital model of the part. This is not simply a copy of the original; the design can be refined or strengthened based on the known points of failure. For example, thin areas can be thickened, sharp corners can be filleted to reduce stress concentrations, and reinforcement ribs can be added.

This digital model serves as the blueprint for manufacturing and can be modified quickly to accommodate fitment issues, alternate use cases, or different appliances.

3. Simulation and CAM Preparation

Before printing, the part design is analyzed for structural integrity, tolerance fit, and printability using CAM tools. For instance, I can simulate load-bearing scenarios, test for weak points, or analyze how the part will perform under heat or vibration—depending on the function of the part.

Once the analysis is complete, I prepare the model for 3D printing using slicing software, optimizing for material, orientation, infill density, layer height, and support structures.

4. 3D Printing in PLA, PETG, or ABS

I use Fused Deposition Modeling (FDM) 3D printing with a choice of thermoplastics:

-

PLA (Polylactic Acid): Biodegradable and easy to print, ideal for non-load-bearing indoor parts.

-

PETG (Polyethylene Terephthalate Glycol): Stronger and more temperature-resistant than PLA, excellent for mechanical parts or mild outdoor use.

-

ABS (Acrylonitrile Butadiene Styrene): Tough and impact-resistant, suitable for load-bearing or heat-exposed applications, such as tool housings or automotive clips.

The part is printed using fine resolution—typically 0.2mm or finer layer height—to ensure high dimensional accuracy and surface finish.

5. Post-Processing and Quality Control

After printing, parts are cleaned, any support material is removed, and tolerances are checked. Where required, parts can be sanded, polished, or chemically smoothed (especially with ABS using vapor smoothing). Holes can be tapped or drilled, and components tested in mock-ups or against the original equipment.

You receive a finished part ready to install and use—often within days of the original request.

Why Use This Service?

1. Cost Efficiency

Replacing an entire appliance or tool due to a small broken part can be expensive and unnecessary. My service allows you to get back up and running with minimal investment.

2. Eco-Friendly Solution

Repairing instead of discarding contributes to sustainability. 3D printing also produces minimal waste, and materials like PLA are biodegradable.

3. Customization

Because each part is designed from scratch, it can be customized to fit modified setups, upgraded hardware, or different operating conditions. You are not locked into the original manufacturer’s design.

4. Support for Obsolete Parts

Many manufacturers stop supplying parts shortly after a product’s lifecycle ends. I can recreate parts for older models, saving vintage or legacy tools and appliances from the landfill.

5. Speed and Local Service

Unlike ordering from overseas or hunting for rare parts, I offer a local, rapid solution. Design and production are typically completed in just a few days, with direct communication throughout the process.

Ideal Applications

This service is ideal for:

-

Home Appliances: Hinges, knobs, clips, drawer runners, gears, spacers.

-

Power Tools: Trigger assemblies, motor mounts, casing brackets.

-

Garden Tools: Handles, safety switches, guards.

-

Automotive Plastics: Interior clips, brackets, dashboard fittings.

-

Office Equipment: Drawer sliders, control knobs, support arms.

-

Vintage Electronics: Switch covers, housing components, button assemblies.

-

Industrial Equipment: Custom grommets, connectors, bushings.

Even if a part seems too obscure or specific, chances are it can be recreated or redesigned to perform the same (or better) function.

Materials Matter: Choosing the Right Filament

Each material has its strengths:

-

PLA is ideal for cosmetic or lightly used parts. It’s precise, affordable, and prints quickly.

-

PETG offers better mechanical performance and can withstand more stress and heat—perfect for functional parts.

-

ABS provides toughness and durability in more demanding conditions, including exposure to sunlight or chemicals.

I will consult with you on the best choice for your part, balancing performance, longevity, and cost.

Here’s an example.

I have a Ryobi 10″ Compund Mitre saw with Laser. I recently broke the Horizontal Mitre Stop lock handle.

This meant that the only way I could lock and unlock the horizontal mechanism was with a wrench or grips. This is obviously not optimal, especially with a spinning saw.

Trying to get a spare part from Ryobi was impossible, and the cost from after market suppliers was, in my mind, prohibitive. So I decided to get onto my CAD software platform and design my own, improved version.

I wanted to use ABS because it is one of the toughter filaments around, and although has a sdden shear point less than PETG, it is stiffer and stronger for this type of part.

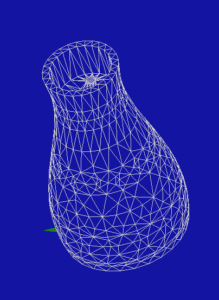

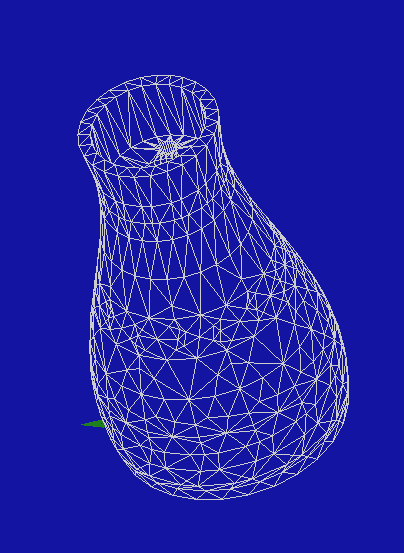

A couple of hours later I had the mesh model designed…..

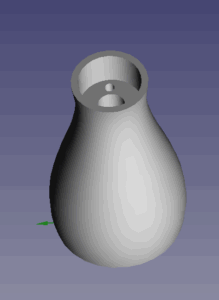

I then checked the shading model to ensure it looked as I expected it to be….

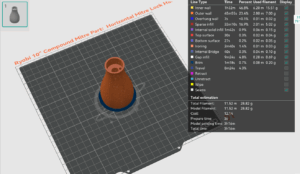

I then exported the .STL mesh and using Orcaslicer, sliced the model to print.

After printing, the model was sanded gently, washed with Acetone to smooth out the layer lines, and then tested for fitting.

The whole process took me around 5 hours, and I ended up with a fully working compound mitre saw that would have cost me over $150 to replace.

Cost, including filament and time ran me about $30.

Had Ryobi still had the part in stock, it would have cost me around $8 + Tax to purchase, $28 dollars + tax to ship, and I’d have ended up with a product that was just as prone to failure as the first one.

I’ve engineered many other spare parts for equipment that have failed, extending the life of the appliance andsaving me lots of money in replacements.

Future-Proofing and Digital Archives

Once your part is modeled in CAD, a digital copy can be stored. If it ever breaks again, another copy can be printed immediately. In fact, multiple copies can be printed up front or produced in different materials for testing. The digital archive is your safeguard for future breakdowns.

Summary

By combining the power of CAD/CAM technology with modern 3D printing, I offer a fast, cost-effective, and eco-conscious solution to an age-old problem: small broken plastic parts that disable entire systems. My service gives individuals and businesses the ability to restore functionality, reduce waste, and extend the life of valuable tools and appliances. Whether you’re a homeowner, DIY enthusiast, technician, or small business, I’m here to help keep your equipment in top shape—one small part at a time.

No Responses